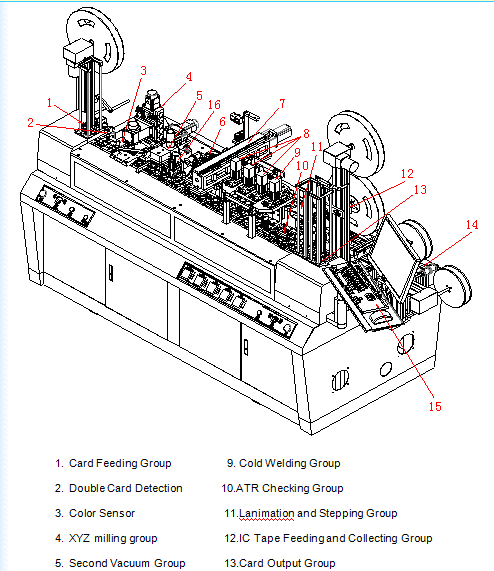

1. Integration of cavities milling, vacuum cleaning, cavity present detection, glue tape punching, lamination, module tape punching, module embedding, ATR testing.

2. Specialized fixture design for card centering system, protecting the milling depth from the influences of the card thickness and dimension.

3. Milling program can be designed by operator, cavity layer can be set 3 layers, each program can be save individually.

4. One milling station can mill different profiles at the same time.

5. Z-Axis moving is realized through guide and ball screw driven by high precision servo motor, to provide the accurate milling depth. Special tool changing program make tool changing is fast and convenient.

6. Cavity present device, double card detection device, card direction detection device and card correction functions. Cavity present device can check if machine mill the cavity on card body or not, if not, machine will be alarm, if yes, card will be moved to next station.

7. Cards transferred through belt driven by servo motor ensure the safety and stability of the machine.

8. Film loading is controlled by serve motor with sensor detection. Faulty module can be distinguished automatically.

9. IC tape feeding and collecting automatically.

10. Bad chips rejected automatically.